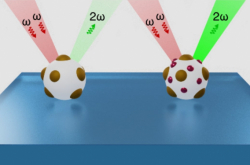

The new holograms reflect light in the same way the original item they've been made copy of would. The technology for that was developed several decades ago; to achieve this effect, an object is first highlighted by a laser, and then the returned radiation is registered by a special photographic element. As result, two types of electromagnetic waves emerge: ones that originate in the radiation source (reference waves), and the others go from the original item (object waves). The areas of the photographic element where these waves' phases coincide become dimmed, thus forming an interference pattern of lighter and darker areas. When one exposes the resulting picture to light, the reference wave transforms into something very similar to the object wave, and a human eye sees the very same object, yet as a hologram.

To produce multiple copies of a hologram, first, a master hologram is created - it is inscribed on a thin layer of photosensitive polymer by using a laser. After that, the polymer is dried, and unexposed areas are deleted. Then the stencil plate with the hologram is transferred on a metal template, which can then be used to emboss microreliefs on different items' surfaces. This is quite crude an explanation of how the holograms work, yet it explains the operating principle: when we look at the hologram from different sides, we see the same reflected light we would've seen if we were to look at the original object.

Still, most holograms have their downsides. First of all, they are weak against temperatures higher than 50 degrees Celsius; they also absorb a lot of moisture from the air. The holographic nanocomposite polymer material developed by ITMO's scientists doesn't have these downsides. In essence, it is a photosensitive acrylic monomer that can contain different colorants and nanoparticles. The hologram encryption method is based on rearranging the material’s components under the effect of radiation.

"Originally, the nanoparticles are evenly distributed in the material. Yet, under the effect of UV radiation of the visual band, the monomer starts to transform into a polymer. The choice of the wavelength depends of the agent used for inducing the polymerization process. Under the effect of light, the compound's molecules form long chains, in other words they polymerize and harden. Polymerization speed in various areas differs slightly, so nanoparticles start moving towards the areas where polymerization goes slower. In practice, that would be from lighter areas to darker ones. After the polymerization process is over, the nanoparticlesremain where they'd moved to. As result, a phased grating is formed, thanks to which we get a hologram," comments Elizaveta Sheklanova, PhD student for the Department of IT in the Fuel and Energy Industry and one of the technology's developers.

After polymerization, the holograms become resilient to temperatures of up to 150 degrees Celsius, and after being laminated they become moisture resistant as well.

Another advantage of the new material is that creating a hologram becomes even easier. There's no need for dark-room conditions, and the whole process takes about five minutes. Also, different kinds of materials - film, glass or special paper - can be used for the hologram's pad.

"Quick polymerization is another of this material's properties. This happens thanks to certain chemical processes. Also, the time needed to create the hologram depends on its layer's thickness: the thinner it is, the less time is needed," explains Elizaveta Sheklanova.

The new technology can be applied in pictorial holography, for producing promotional merchandise, as well as for protecting important documents and other items. Thus, holograms can contain several images made at different angles, complex kinetic effects, hidden images, fine line printing and other protective elements. At any attempts to remove the hologram or mechanical damage, the hologram deteriorates.

The scientific results of ITMO's research team were presented at the 20th Moscow International Salon of Inventions and Innovative Technologies "Archimedes", where it was awarded the event's gold medal. The technology has already been patented in Russia, and an article with a report has been published in the Optics and Spectroscopy journal.

Article: J. A. Burunkova I., Yu. Denisyuk, D. I. Zhuk, E. B. Sheklanova (2017), Holographic nanocomposite and a related diffraction element, Optics and Spectroscopy.