Skoltech is a young university that was created under the guidance of the Massachusetts Institute of Technology (MIT). As for today, the laboratory where Dmitry Teterukov works has only been around for two and a half years, yet it has already received several international awards and actively works on both Russian and international robotics market. Its recent major accomplishment was winning the Russian round of the EUROBOT-2016, which is one of the most prestigious international robotic contests.

"The robotics market is growing rapidly; many developed countries focus on this field. In 2015, robot sales increased by 15% to 250 thousand units, which is by far the highest level ever recorded for one year. This growth was mostly stimulated by the electronic industry and metals industry. By 2018, we expect this number to be about 414 thousand," shares Dmitry Teterukov.

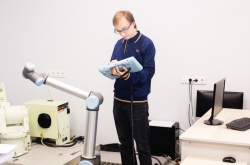

Dmitry Teterukov

Dmitry Teterukov

As of now, the robotic market's leaders are Japan and Germany. Japan focused on robots some 40 years ago and has been successful ever since, yet it is now being surpassed by South Korea and Singapore, where there are 478 robots per 10,000 human employees now. Among the leaders is also Taiwan, where the electronic industry is highly developed. In China, the robot density is half the world's average at 33 robots per 10,000 employees. In Russia, this indicator is really low: 1-2 robots per 10,000 employees, and the annual sales of robots is between 500-600 units. This number is gradually growing, as Russia gradually improves its position on the world's market.

So, why does the robotics market continue to grow, and new drones get more and more popular with enterprise owners? Nowadays, many companies set sights on complete automation and thus expenses reduction, which makes introducing new robotic systems even more relevant. The success of some companies in using new robotic technologies is evident, and demonstrates how robots are becoming a part of our lives.

The Tesla Inc. Company has five thousand employees and 600 robots. This is the approach that Elon Musk, the company's founder and pioneer of technological initiatives, uses to attain complete automation. Tesla Inc. is an example of an enterprise that rapidly develops in both informational and industrial fields, though one can often hear the misconception that it's no longer competitive. Most of Tesla's robots are used for welding, dyeing and other similar functions.

Robots at an enterprise

Robots at an enterprise

One more example of a successful project that makes use of robots is the Amazon Company which conquered USA's retail market. Amazon has several major logistics centers that used about 30-35 thousand robots back in 2015. As of now, their number has increased to 45 thousand. Using the robots produced by a robotics enterprise bought for 800 million dollars allowed Amazon to increase its performance by 20%.

Another renowned company is Japan's Fanuc that has been an independent robot production company since 1972. The enterprise has only five and a half thousand employees at profits of about 1.7 million dollars, and is an indisputable leader holding 65% of the world's robotics market. For instance, if you use an iPhone, know that its frame was made by a Fanuc CNC-robot. Competing with such a long-lived enterprise is problematic; yet, not only traditions and experience can guarantee one's success.

The Danish Universal Robots Company is a great example of a company with not much history but great success. Their idea of collaborative robots made them one of the robotics market's leaders. The company's robots are not just equipment, but safe systems that don't call for any additional safety features.

The history of robotics companies has always been closely intertwined with universities. This is because the robotic industry calls for non-standard solutions which are best created by commercial specialists and academic staff and students working together. A good example of that is the DJI Company which was created at one of Hong Kong's universities in 2006. By 2015, it was compared to Boeing for its contribution to the development of aerial devices.

The company's latest invention is the portable Mavic Pro drone that weighs 843 grams and can be folded and carried in a bag. Such drones can be good for both photographers and cameramen, as well as extreme sportsmen.

The drone carries a special camera and can be controlled by gestures. Also, it can hover and trace a person's face.

Mavic Pro drone

Mavic Pro drone

"Sooner or later, robots will have to learn to interact with each other. Steve Jobs did a revolution, as he proposed using intuitive gestures instead of a keyboard. Even a child can quickly learn that. In future, a common interface for controlling robots is to be created as well," commented Dmitry Teterukov.

His students also shared about the projects Skoltech works on.

EUROBOT and robotic cars

Artem Pavlov, PhD student of the Intelligent Space Robotics Lab shared about the EUROBOT contest.

"Eurobot is great as you have to develop everything from scratch. Of course, there are mentors, yet architectures, software and all of the development process has to be done by the participants. The experience you get from taking part in the contest can be used in future practical work on inventions that can be then brought to the market," comments Artem.

Skoltech

Skoltech

The participants get experience in developing both hardware and software. According to the PhD student, they usually develop good hardware, but software is sometimes lacking as there are not enough good programmers. The contest's winners get valuable prizes - great job offers from leading IT and robotics companies both from Russia and abroad.

Skoltech's team that participated in EUROBOT-2016 and won the Russian round is now working on the Pick ToGo project that aims to solve the problem of storage units' automation. One of the difficulties of warehousing business is picking (i.e. when the robot has to find and pick a pallet with several different types of boxes). Currently, it’s people who distribute the boxes on their positions. The startup's idea is to use a mobile platform instead. The industrial robot will be able to lift lighter boxes (up to 10 kg) and even heavier ones (up to 20 kg) by using additional gear. The robot will work 10-15% slower than humans, but allow to completely automate the process. Another important task is to create a reliable computer vision system. The robots have to learn to discern boxes by angles and shape, as boxes don't always have bar codes on them. There are several challenges to this problem. For instance, there are still no reliable solutions for computer vision based on RGBD cameras for identifying homogeneous objects; thus, working on the project implies doing some sound scientific research. Machines by the RoboCV Company, a Skolkovo resident, will be used to transport the palletes. The RoboCV Company is an example of a successful Russian robotic enterprise that focuses on warehouse automation. In just five years of work, the company has introduced several of its projects. Among its customers are Volkswagen, Samsung and other large companies.

According to Skoltech's representatives, Russia also has to develop competencies that have to do with drone control. Those who are interested in such topics as computer vision and unmanned aircrafts would surely find Skoltech's project on developing driverless cars interesting. As for now, there are special devices that are tested on cars used by Uber and Google, namely Nissan X-trail cars. The project focuses on two tasks: first, fixing the cars with computer vision so that they will perceive their surroundings, and then automating the cars so they would not require drivers. The developers also plan to use the system for golf cars, as its easier from the legislation point of view (as golf cars do not fall under restrictions on car modifications), as well as for trucks that are used on corporate premises. Samsung's plant near Moscow already showed interest in the latter, as it offers great opportunities for reducing expenses.

Eurobot-Russia

Eurobot-Russia

Smart factory

Dmitry Mironov, another PhD student at Skoltech, explained the concept of a smart factory. A smart factory is a concept of such an enterprise where production is done by robots only. So, how can robots interact with each other? First, an "electronic version" of the product is created per the customer's demands. Then, responsibilities are distributed between the robots. Special sensors send data to a cloud that connects them. Yet, one should not think that there are no employees working at a smart factory. People do the maintenance and service work, which is especially important, as outage time costs a lot - for a Samsung production line, that would be about 5 thousand dollars a second.

From an economic point of view, smart factories are most effective. The product's life cycles are becoming shorter, and the number of different products is constantly growing. The cost of production in China is becoming more expensive as well, and will soon reach European costs, thus manufacturers aim to bring the production to their home countries.

"In an ideal situation, each country will have its own small factories that can produce a wide range of products without having to readjust anew, as all one would have to do is load a new task for production. Thus, both manufacturing and shipping will become more cost effective," explains Dmitry Mironov.

Nowadays, the RDF language is used for interacting with robots. It is quite simple: there are only three members of a sentence - subject, predicate and object. You can't express much by using such a language, but it can be easily understood by robots who need a simple language for interacting with each other and coordinating their work. To further reduce the costs, the robots' computational capacities can be made cloud-based.

Robots are becoming more complex and enter all fields of lives. This year, OpenAI's employees conducted an experiment where robots were to create their own language. They were to complete different tasks: for instance, one robot had to persuade another to move to a certain point. Robots were given an opportunity to communicate, but at first their messages didn't make any sense. Yet, in the end robots learned to talk, invented their own words and even used sentences. That became possible with the help of another high-end technology – neural networks.